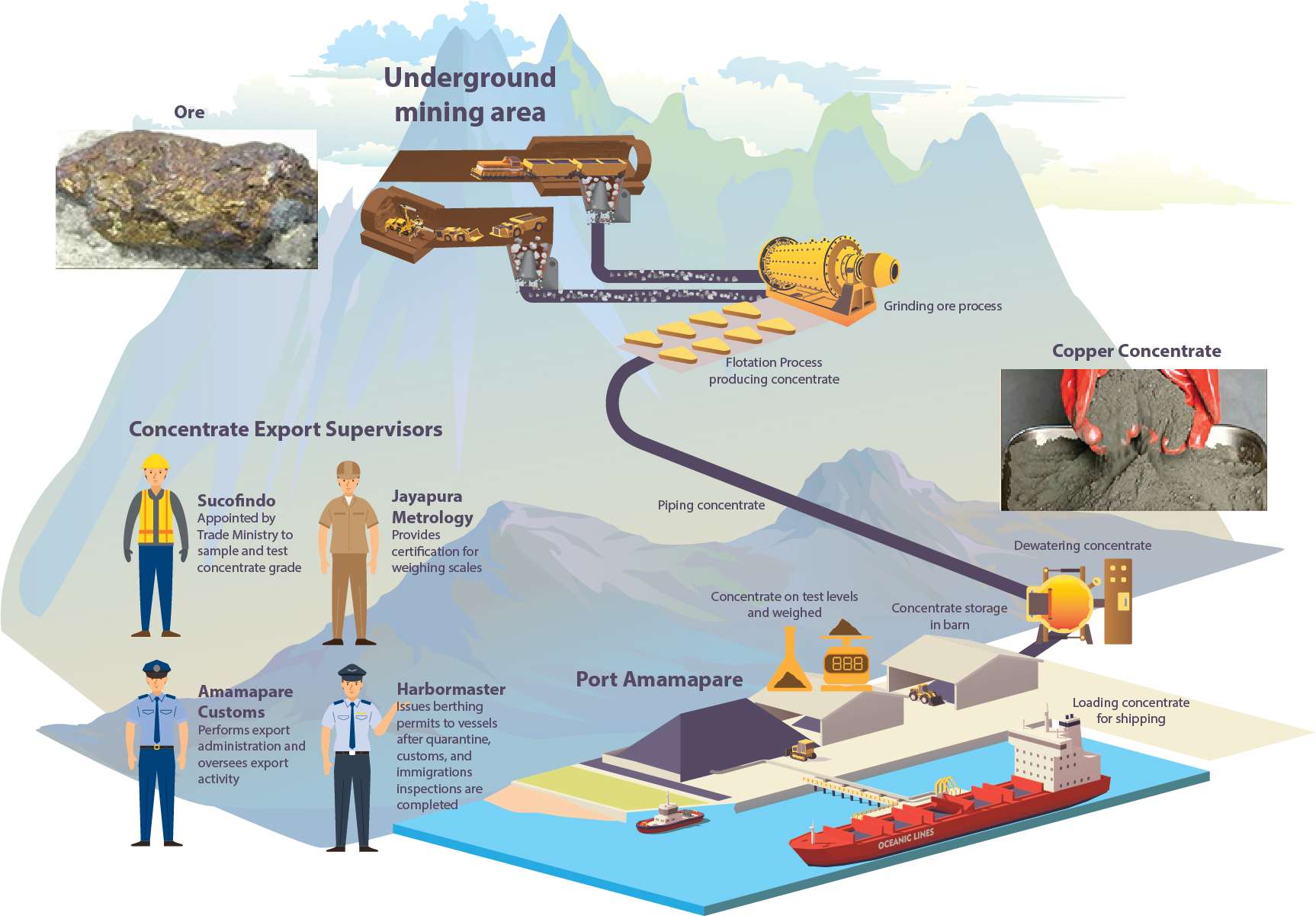

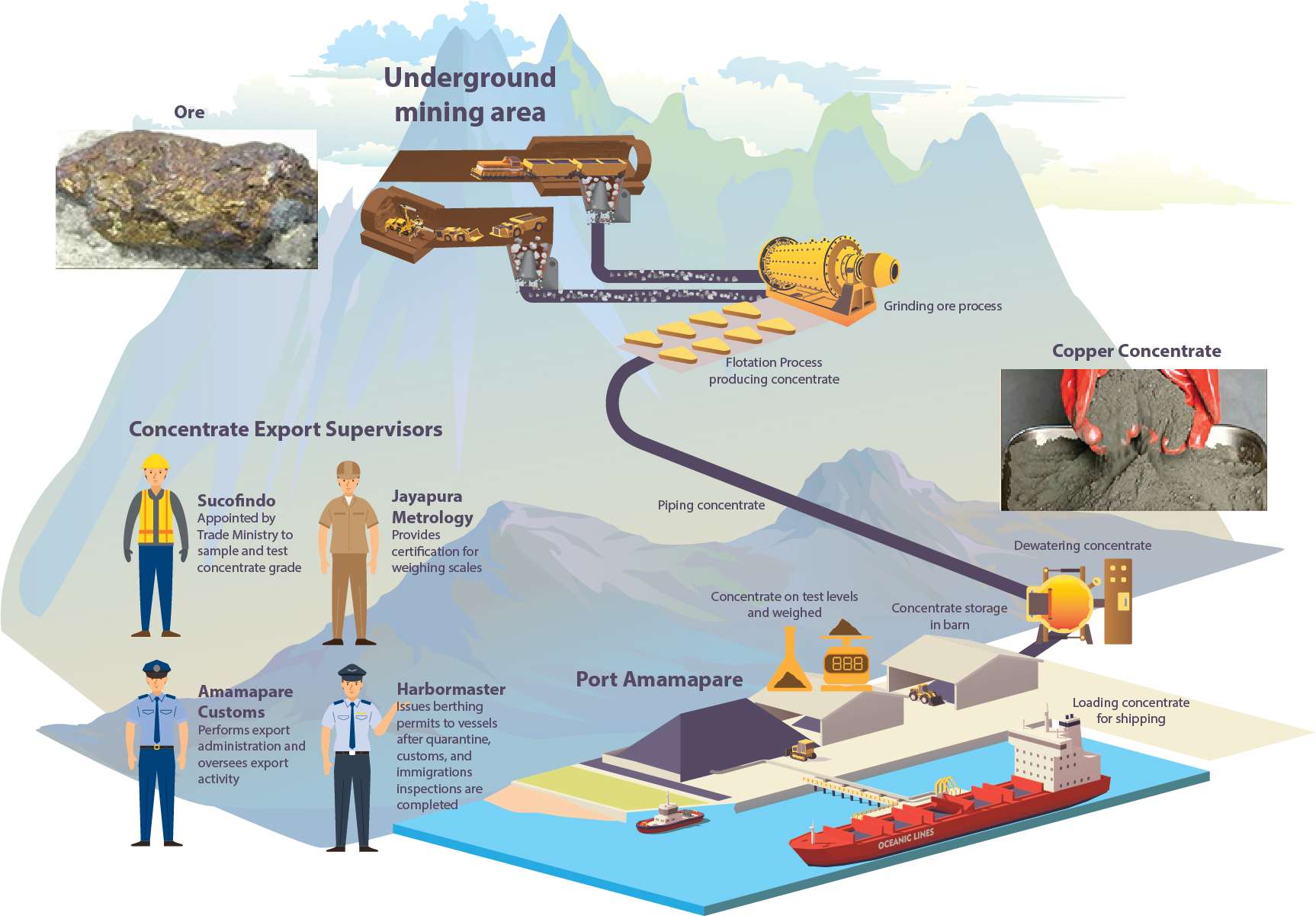

PT Freeport Indonesia (PTFI) currently employ the underground mining method. Ore extracted from the mine is hauled to the mill to be crushed and ground into very fine particles. This is followed by a flotation process using a reagent based on alcohol and lime to separate concentrate containing copper, gold and silver minerals. The residue with no economic value (tailings) is channeled by means of a river to a deposition area in the lowlands.

Concentrate in the form of slurry is channeled from the mill by means of a 110 km long pipeline to a dewatering plant in Amamapare port. After it is dewatered, the concentrate, which is PTFI’s final product, is shipped to smelters.

*Click image to see details

*Click image to see details

Mining: includes drilling and blasting, loading and hauling ore, and crushing to produce copper ore.

Processing: includes grinding, flotation, and dewatering to produce copper concentrate, which buyers pay for the copper, gold, and silver content.

Copper concentrate is PTFI’s final product, with value added 95%.

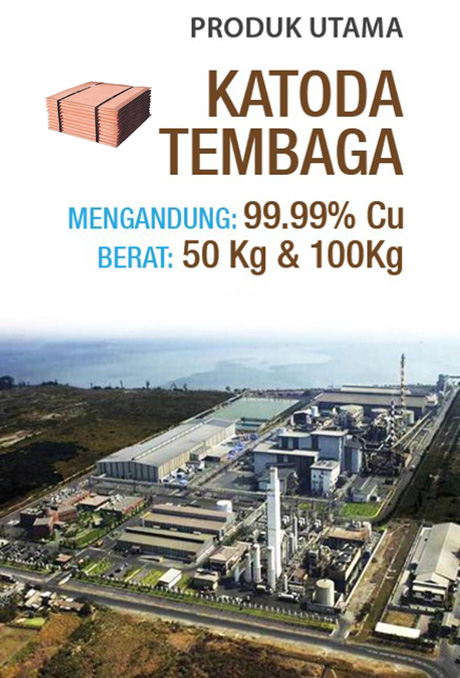

Refining operations in Gresik – East Java

Refining operations in Gresik – East Java

Kami menghimbau para pencari kerja untuk berhati-hati dan mewaspadai beragam modus penipuan perekrutan yang mengatasnamakan PT Freeport Indonesia. Dalam setiap proses rekrutmen dan penerimaan karyawan, PT Freeport Indonesia maupun konsultan rekruitmennya tidak memungut biaya apapun.

Untuk melihat lowongan, silakan akses melalui link berikut: ptfi e-recruitment

Untuk melihat informasi magang, silakan akses melalui link berikut: Internship Program